- Super User

- 2025-01-03

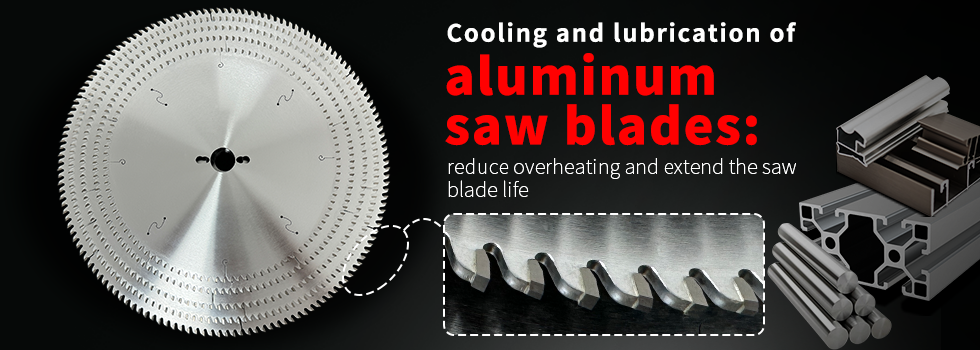

Ukupholisa nokuthambisa kwe-aluminium saw blades: ukunciphisa ngokweqile futhi k

Lapho usika ama-aluminium alloys, ukupholisa nokuthambisa kwe-aluminium i-blade kuyintokubalulekile,Ngenxa yokuvuselelwa okuphezulu okuphezulu kanye nephuzu eliphansi lokuncibilika le-aluminium alloy bakhonaKulula Khiqiza ukushisa okuningi ngesikhathi sokusika inqubo,okuholele ekutholweni ngokweqile kwe-saw blade, ukuncibilika kwe-aluminium alloy nokunamathela ku-saw blade, okuthinta Ukusika umphumela futhi wabona impilo ye-blade.lesi sihloko kuzokwenza ukuhlola okujulile kokubaluleka kokupholisa nokuthambisa i-aluminium saw blades kanye nezindlela zabo ezihlobene nabo.

1.Ukubaluleka kokupholisa nokuthambisa:

Lapho usika i-aluminium, okulandelayoizindaba isifisothintaenza ngendlela ethileingxube ikhwalithi futhiinsizakaloimpilo iwa- le khasiwabona blade:

- Ukutholwa kokushisa kanye nokungenzi ngokweqile: I-Aluminium Alloy izodonsa ngokushesha ukushisa ngesikhathile khasiInqubo yokusika, futhi izinga lokushisa eliphakeme elikhiqizwe yi-saw blade ngesikhathi senqubo yokusika kulula ukudala umonakalo ku-saw blade ngisho nangokoqobo okwenza banamathele ebusweni bebala elithayishwe, ngaleyo ndlela bathinta ukunemba nokusebenza kahle.

- Ukunxusa kwe-Aluminium Alloys: Ngenxa yendawo ephansi yokuncibilika kwama-aluminium alloys, ukushisa okukhiqizwe ngesikhathi senqubo yokusika kungahle kuncibilike futhi kunamathele ama-aluminium ama-aluminium ama-aluminium ama-aluminium ahlanganiswe ku-saw. abangele ukusika kabi, wabona ukungcola okukude nokulimala komhlaba.

- Ukugqokwa kwe-saw blade: okuqhubekayo okuphezuluizinga lokushisa nokubanda Futhi ukungezwani kuzokwandisa ukugqokwa kwale blade, okuholele ekufushaniswe kwempilo. Ngaphandle kokupholisa okufanele nokuthambisa, ukunamathela noma izinto ezingaphezulu kwe-saw blade kungagqokwa ngokushesha, kunciphisa impilo yayo yenkonzo.

Ngakho-ke, ukupholisa okunengqondo nokuthambisa kunganciphisa ngempumelelo ukugcwala ngokweqile, ukugwema ukubheja kwe-aluminium, kunciphisa ukungqubuzana kwinqubo yokusika, ngaleyo ndlela kunwebe impilo yenkonzo ye-saw blaw kanye nekhwalithi yokusika.

2.Izindlela Zokupholisa

Lapho usika ama-aluminium alloys, okulandelayo kukhonaIzindlela Ezivamile Zokupholisa:

2.1 Fafaza ukupholisa

Ukuphola kwe-Spray ukufafaza okupholile ngokusebenzisa i-nozzle endaweni yokusika futhi kuphole iphuzu lokusika ngqo. Ukuphola kwe-Spray kungasusa ngokushesha ukushisa okwenziwe ngokusika, ukugwema ukunqwabelana kokushisa endaweni yokusika, ngaleyo ndlela kunciphise izinga lokushisa le-blade.

- Izinzuzo: Kunganciphisa ngempumelelo amazinga okushisa we-saw blade, wehlise ukunamathela kwama-aluminium chips.

- Okubi: Ukupholisa isifutho kudinga ukwakheka okuqondile kwe-nozzle kanye nokulawula okupholile, okungaphumela ekupholiseni okungekuhle uma ukugeleza okupholile kuphansi kakhulu.

2.2 Ukungena -pholile

Ukupholisa kwe-Infiltration inqubo yokwahlukahlukana noma ngokuphelele i-blade elibunjiwe ku-coolant ngesikhathi senqubo yokusika, ukuqinisekisa ukuthi indawo yokusika futhi ingaphezulu le-saw blade lihlala ligcinwa emazingeni okushisa aphansi.

- Izinzuzo: Umphumela wokupholisa uyamangalisa, ongaqhubeka futhi anciphise ukushisa kwecala le-saw.

- Okubi: Inezidingo eziphakeme kakhulu ze imishini, rilingana uhlelo olukhethekile lokupholisa, futhi lungadala imfucuzaMahhala

2.3 Ukupholisa igesi

Ukupholisa igesi ngokuvamile kusetshenziswa umoya ocindezelwe noma igesi yokupholisa ukunciphisa izinga lokushisa le-saw blade. Ikakhulu kwezinye izimo lapho kungekho luhlelo lokupholisa olimazayo, ukupholisa igesi kungasetshenziswa njengenye uhlelo.

- Izinzuzo: Izidingo zemishini ziphansi. Kulula futhi kulula ukusebenza kuyo, futhi ngeke kubangele ukungcoliswa koketshezi olupholile.

- Okubi

3. Indlela yokuhlanza

3.1 Amafutha okugcoba

Ukusetshenziswa kwamafutha okuthambisa okuyisisekelo kunganciphisa ngempumelelo ukuxabana phakathi kwe-aluminium alloy kanye ne-blade ngesikhathi senqubo yokusika ukugwema ukuncibilika kwe-aluminium alloy ukuncibilikisa nokunamathela kulawo mandla.

- Izinzuzo: Amafutha wokuthambisa angakha ifilimu elincanyana, anciphise ukuxabana, ukuvikela ubuso be-saw blade futhi bandise impilo yenkonzo.

- Okubi: Uwoyela wokugcoba kulula ukungcolisa imvelo yokusebenza futhi kudingeka asulwe njalo.

3.2 Ama-lubricant asuselwa emanzini

I-lubricant esekelwe emanzini iyingxube yamanzi nokuthambisa ukuze kwakhiwe uketshezi olunendima embaxambili yokupholisa nokuthambisa. Izithako ezisuselwa emanzini zivame ukuqukethe izingxenye zokulwa nokukhulisa, ezinganciphisa ngempumelelo amazinga okushisa endaweni yokusika futhi athuthukise umphumela wokusika.

- Izinzuzo: Uma kuqhathaniswa namafutha okuthambisa, ama-lubrices asuselwa emanzini abangela ukungcoliswa okuncane emvelweni futhi abe nomphumela opholile ovelele.

- Okubi: Ukuqoqwa koketshezi okususelwa emanzini kudinga ukulungiswa kahle, ngaphandle kwalokho kungathinteka umphumela.

3.3 i-grif eqinile eqinile

Izithambisi eziqinile zinganikeza ukuthambisa endaweni yokusika, kepha zivame ukusebenza ezindaweni ezithile ezikhethekile zokusika noma ezisetshenziswa ngokuhlanganiswa nezinye izindlela zokupholisa.

- Izinzuzo: Izithambisi eziqinile azingcolisi imvelo futhi zilungele ukucaciswa kwemishini.

- Okubi: Umphumela wezithako eziqinile akayona ebaluleke njengalezo zokuthambisa eziwuketshezi futhi angadinga ukutshalwa kwemali okuphezulu kwezobuchwepheshe.

4.Ukusetshenziswa okuhlanganisiwe kokupholisa nokuthambisa

Izinhlelo zokupholisa nokuthambisa ze-aluminium saw blades kufanele zihlanganiswe futhi zisetshenziswe ngokwezidingo ezithile zokucubungula. Ngokuvamile ukukhuluma, ukupholisa nokuthambisa kungasebenza ndawonye ngalezi zindlela ezilandelayo:

- Ukupholisa nokuthambisa ngasikhathi sinye: ngokwesibonelo, ukugcotshwa kwe-spray kugcotshwe ngasikhathi sinye, ukuqinisekisa ukuthi i-saw blade ingapholiwa kuphela kepha futhi incishise ukungqubuzana endaweni yokusika.

- Ukupholisa okuphakathi nendawo nokuthambisa: Kwezinye izinqubo zokusika, ukupholisa kokupholisa kanye nokuthambisa izindlela kungamukelwa ukuze kutholwe izinguquko ezindaweni ezahlukahlukene noma ngejubane lokusika.

5.Conclusion

Ukupholisa nokuthambisa kokusika kwe-aluminium ukubona ama-blades kudlala indima engenakufinyeleleka ekwenzeni ngcono ukusebenza kahle, ukunciphisa ukugqoka kwe-saw blade futhi kunwebe impilo yenkonzo yama-blades abona. Ukukhetha okunengqondo nokusetshenziswa kwezindlela ezifanele zokupholisa (ezifana nokupholisa kwe-Spray, Ukupholisa i-Infiltration noma i-Loging) kanye nezindlela zokuthambisa amanzi, njengokuthambisa okuqinile) kunganciphisa ngokuphumelelayo ukushisa okwenziwe ngempumelelo ngesikhathi senqubo yokusika nokunciphisa Inkinga yokunamathela ye-Aluminium Alloy, ngaleyo ndlela iqinisekise ukuthi inqubo yokusika ibushelelezi, isebenza kahle futhi inembile.in, ukwakheka okuhle kohlelo lokupholisa nokuthambisa alukwazi kuphela Nweba impilo ye-saw blade, kepha futhi ithuthukisa ukusebenza kahle kokukhiqiza futhi inciphise izindleko zokulungiswa kwemishini. Ngakho-ke, ukukhetha indlela efanele yokupholisa nokuthambisa kubalulekile ukuthuthukisa ikhwalithi kanye nokusika kwe-aluminium.