- Super User

- 2024-12-27

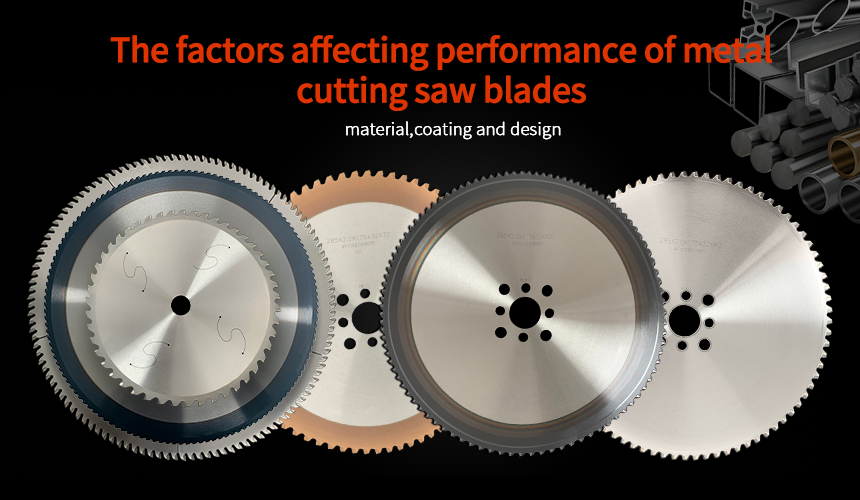

Izici ezithinta ukusebenza kokusika kwensimbi kwabona ama-blades: izinto ezibona

Ukusebenza kwezinsimbi zokusika kwensimbi kwatholwa kuthonywa yizici eziningi, izici eziphambili ezibandakanya ibala lezinto ezibonakalayo, ukuhlanganisa kanye nokuklanywa kwalesi simo se-blade. IBlade.Imininingwane elandelayo ichaza umthelela walezi zici ezintathu ekwenzeni ukugawulwa kwensimbi kwabona ama-blades:

1.SAW Blade Okubonakalayo:

Izinto ezibonakalayo ze-saw blade kungenye yezinto ezibalulekile ezithinta ukusebenza kwayo kokusika, futhi izinto ezahlukene zinobunzima obuhlukile, ukuqina kanye nokugqokwa kwensimbi) Ukusika insimbi okuwukunciphisa kwensimbi (HSS), carbide nokunye.

I-Speed Speed Speed (HSS): I-HSS uhlobo lwento esetshenziswayo esetshenziselwa ukugawula insimbi, enobunzima obuhle nokuvikelwa kokushisa.AwApple i-blade ilungele ukusika i-hardness metal metal, ukunika amandla i-bear high temperture kanye nengcindezi, kepha kuqhathaniswa Nge-Carbide, ukumelana kabi kwemvelo, efanelekile ukusika okusheshayo.

Carbide:I-Carbide saw blades inobunzima obuphakeme futhi igqoke ukumelana, ilungele izinsimbi ezinobulukhuni obuphezulu (njengensimbi engenasici, i-njll.) Kukhulu, kulula ukugqashula ngaphansi komthelela.

Ukukhethwa kokuqukethwe kuncike ohlotsheni lwensimbi ukuze kuncishiswe futhi kuncishiswe izidingo.Matadium anobunzima obukhulu kunganciphisa izinsimbi ngobulukhuni obukhulu, kepha ngasikhathi sinye, kudinga ukuhlanganiswa nokuqina.

2.I-coating:

Ukuhlanganiswa kwensimbi ukusika okubonakale kungathuthukisa kakhulu ukumelana nokugqoka, ukumelana nokushisa kwezinto zokwakha ama-taitium.comon (Tin, tialn), njll. Lezi zimbozo azikwazi ukuvikela i-saw blade , kodwa futhi nokwenza ngcono ukusika kahle.

I-Titanium Nitride (TIN) Coatide: I-Tin Coating ivame ukusetshenziselwa insimbi enesivinini esikhulu ne-carbide saw saw blades. Kungathuthukisa ubulukhuni futhi kugqoke ukumelana kwe-saw blade komhlaba, kunciphisa ukungezwani futhi kwandise impilo yenkonzo.Inganciphisa ukushisa okwenziwe ngesikhathi sokusika.

Titanium aluminium nitride (tialn) coatide: Le coating iyi-jwayelekileI-LY isetshenziselwa ukunciphisa izinhlelo zokusebenza ne-Ukushisa okuphezulu nomthwalo omkhulu. Inokumelana nokushisa okuphezulu okuphezulu futhi ingamelana namazinga okushisa aphezulu wokusika. Kufanelekile ukuthi kube nzima ukusika izinto ezifana nensimbi engenasici kanye nensimbi ye-alloy.

I-titanium carbide (tic) coating: titanium carbide coatings ukumelana okuhle nokuvimbelais Ilungele izinhlelo zokusebenza lapho kufunwa khona ukumelana khona.

Indima ye-coatis ukunciphisa ukungqubuzana phakathi kwamathuluzi nensimbi, futhi kunciphiseizinga lokushisa nokubanda Ngesikhathi sokusika, ngaleyo ndlela kuthuthukise impilo yenkonzo kanye nekhwalithi yokusika ye-saw kerle.moreover, ukunamathela kuvimbela ama-chips wensimbi ekunamathela ebusweni be-saw blade, uqinisekise ukusebenza kahle.

3.I-Blade Design:

Idizayini ye-saw blade ikakhulukazi ibhekisa kwisimo samazinyo, isivunguvungu samazinyo, ubukhulu kanye nokwakheka kwalesi sihloko, ukuqina kwekhwalithi eqondile ekusebenzeni kahle, ukuqina kanye nokusika kwekhwalithi ye-saw blade .

Ukwakheka kwamazinyo kanye ne-tooth pitch: ijamo lamazinyo (njengamazinyo aqondile, amazinyo aqondile, amazinyo e-wavelform, njll.) Futhi i-tooth pitch izothinta ubushelelezi nokunemba kokusika. I-pitch encane ilungele ukusika okuhle, ngenkathi iphimbo elikhudlwana lilungele ukusika okusheshayo kwensimbi enkulu. Idizayini yokwakheka kwamazinyo kufanele ikhethwe ngokuya ngobulukhuni, ubukhulu kanye nokusika izidingo zezinto zokusika.

Idizayini yezinyo eqondile: Ilungele ukusika insimbi esindayo, inikeze amandla anamandla okusika, kepha kulula ukukhiqiza ukudlidliza okukhulu lapho usika.

I-Bevel Tooth Design: Ilungele izimo lapho kudingeka khona isivinini esiphezulu kanye namabutho amancane okusika.

I-WaveForm Teeth Design: Imvamisa isetshenziselwa ukuthuthukisa umphumela wokusika ngenkathi kunciphisa ukunqwabelana kokushisa.

Ubukhulu be-blade: Ubukhulu be-blade buthinta ngokuqondile ukuqina nokuqina kokusika.Thicker ukubona ama-blades ngokuvamile ahlala isikhathi eside, kepha kungakhulisa umthwalo ngenkathi kuwukusika izicelo lapho ukusika okuphezulu okulula. Kuyadingeka, kepha ukuqina kumpofu.

I-Chip Groove Design ye-saw blade:

Amanye ama-blade aklanywe ngama-grooves akhethekile we-chip angenza ngempumelelo ama-metal chips avela endaweni yokusika, anciphise umthelela wama-chips wensimbi ku-saw blade, futhi ngenxa yalokho uthuthukise ukusebenza kahle nekhwalithi.

I-Blade Sakhiwo Sakhiwo Design:

Ukwakheka kwangaphakathi nangaphandle kwebala elitholwe, njengokuma komgodi wesikhungo kanye nesakhiwo sokusekelwa, kuzothinta ukulingana nokuqina kokusika. Ama-blades asezingeni eliphakeme ajwayele ukuklanywa ngokusatshalaliswa okunengqondo kanye nokwakhiwa okuqinisayo ukuze aqinisekise ukuthi ahlala ezinzile ngesikhathi sokusika futhi awathambekele ekuguqukeni.

Isiphetho:

Izici eziphambili ezithinta ukusebenza kwezinsimbi zokusika zensimbi ezibunjiwe ziyizinto ezibonakalayo, ukuhlanganisa kanye nokuklama.Into ebonakalayo inquma ubulukhuni besikhathi, ubulukhuni kanye nobubanzi besicelo, i-coating iyathuthukaukumelana nokugqokwa, ukumelana nokushisa nokuphikiswa kokugqwala kwama-blades abona. Idizayini inethonya ekusikeni komphumela kanye nokusebenza kahle, ukuqina kwethonya lokusika.ngokuba yilezi zinto kubhekwe, i-blade elifanele kakhulu lingakhethwa ukuze kuthuthukiswe ukusebenza kahle kanye nokusika kwensiza yethuluzi.