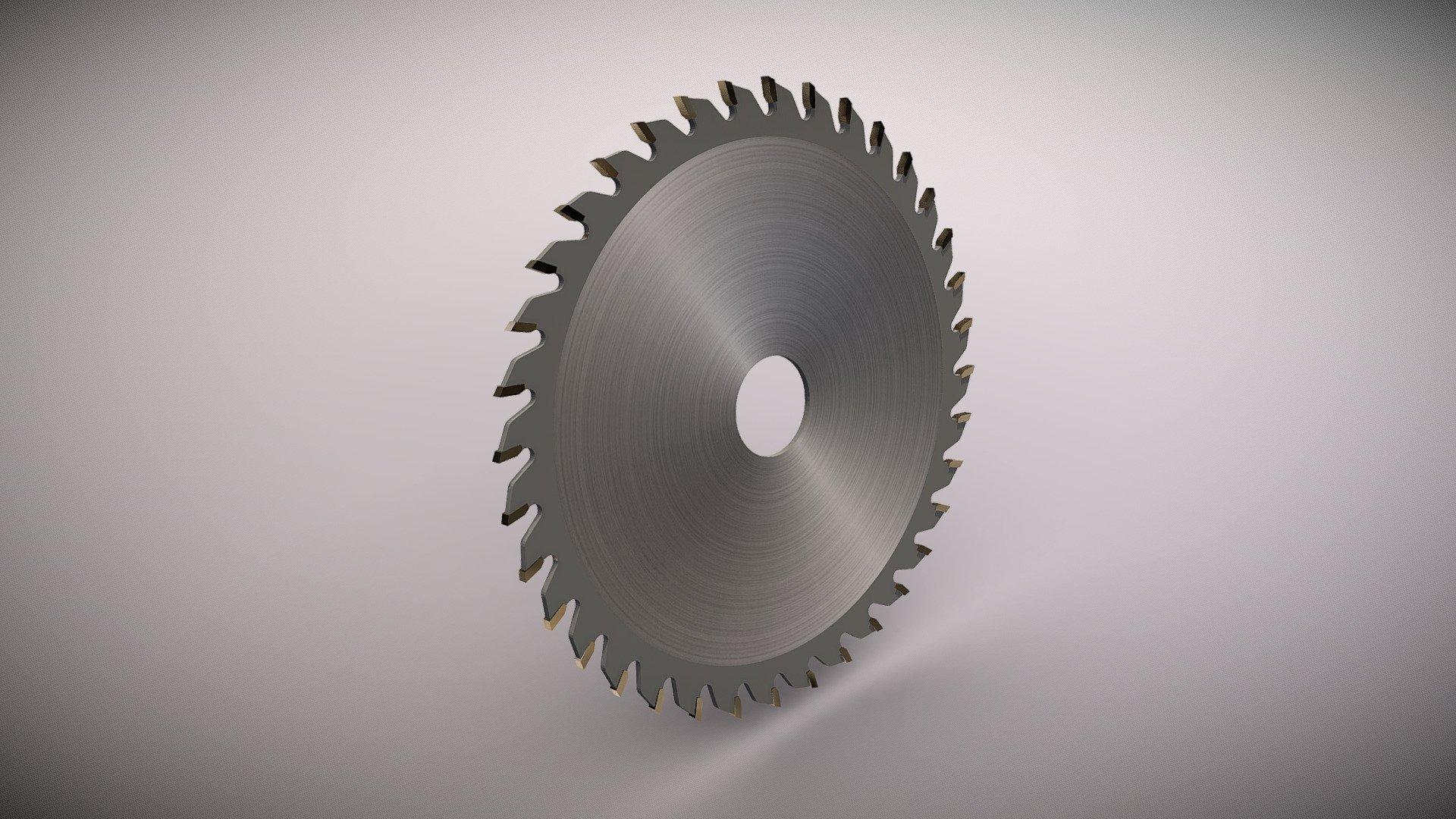

Many customers ignore some "small means" to maintain and protect the saw blade when using the saw blade, resulting in the same saw blade having completely different evaluations in the hands of different customers.

1. If the saw blade is not used immediately, it should be laid flat or hung up by using the inner hole. Do not stack other objects or step on the saw blade laid flat, and pay attention to moisture and corrosion.

2. When the saw blade is no longer sharp and the cutting surface is rough, it must be reground in time. Grinding cannot change the original angle and destroy the dynamic balance.

3. The inner diameter correction and positioning hole processing of the saw blade must be done by the factory. If the processing is not good, it will affect the use effect of the product and may cause danger. In principle, the reaming hole should not exceed the original hole diameter of 20mm, so as not to affect the balance of stress.

Four. Alloy grinding wheel selection.

1) The bonding strength of the resin bonded diamond grinding wheel is weak, so the self-sharpness can be good during grinding, it is not easy to clog, the grinding efficiency is high, the grinding force is small, and the grinding temperature is low. The disadvantage is poor wear resistance and abrasive wear Large, not suitable for heavy duty grinding.

2) Vitrified bond diamond grinding wheel has better wear resistance and bonding ability than resin bond, sharp cutting, high grinding efficiency, not easy to generate heat and clogging, less thermal expansion, easy to control precision, disadvantages are rough grinding surface and high cost .

3) The metal bond diamond grinding wheel has high bonding strength, good wear resistance, low wear, long life, low grinding cost, and can withstand large loads, but has poor sharpness and is easy to clog.

4) The abrasive particle size has a certain influence on the clogging and cutting capacity of the grinding wheel. Compared with the fine grit, the coarse grit will increase the wear of the cutting edge when the cutting depth is large, otherwise the grinding wheel is easy to clog.

5) The hardness of the grinding wheel has a great influence on clogging. The high hardness of the grinding wheel has a high thermal conductivity, which is not conducive to surface heat dissipation, but it is beneficial to improve processing accuracy and durability.

6) The concentration selection of the grinding wheel is an important feature, which has a great impact on the grinding efficiency and processing cost. If the concentration is too low, the efficiency will be affected. Otherwise, the abrasive grains will fall off easily, but the best bond concentration range is also good.